Potting & Conformal Coating

Protection for PCB Assemblies in Harsh Environments

Get A Free Quote

Environmental Protection for PCB Assemblies

At Contract Production, we offer PCB conformal coating, potting, and encapsulation services providing protection for electronic components against moisture, chemicals, dust, and extreme temperatures in harsh environments. Our conformal coating and potting solutions enhance the reliability and durability of PCB’s assemblies preventing corrosion and moisture damage in the most harsh environments.

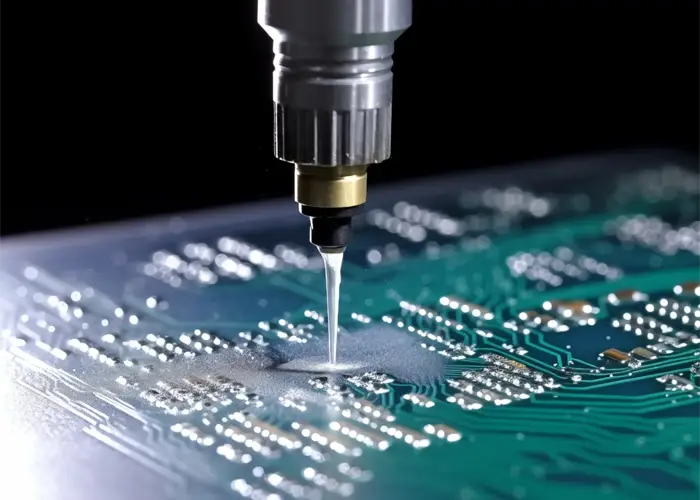

What is PCB Conformal Coating?

PCB conformal coating is a thin protective layer applied to circuit boards to safeguard them against environmental factors such as humidity, corrosion, and chemical exposure. It enhances the performance and lifespan of electronic assemblies while maintaining electrical insulation and mechanical stability.

Key Benefits of Conformal Coating

- Protects circuits and components against moisture, corrosion, and contaminants

- Enhances reliability and performance in harsh environments

- Provides electrical insulation

- Prevents short circuits and failures

- Increases the lifespan of PCBs

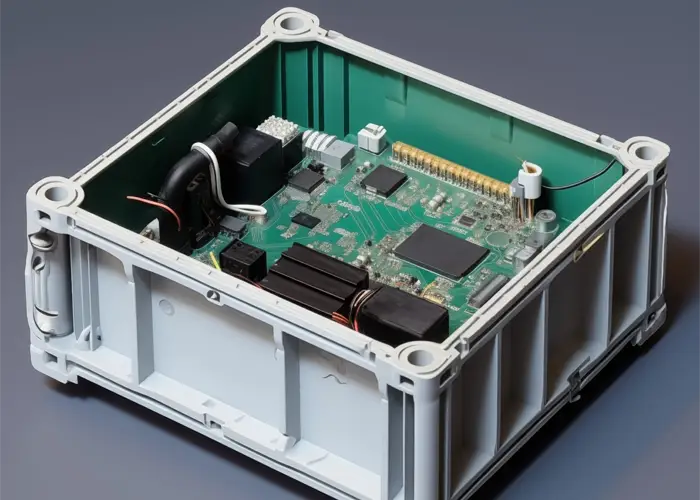

What is Potting & Encapsulation?

Potting and encapsulation involve covering electronic components with a protective resin to shield them from harsh environmental conditions. These methods provide superior insulation, mechanical support, and thermal management, ensuring the longevity and functionality of sensitive electronics whilst additionally providing protection of sensitive IP within a potted enclosure.

Key Benefits of Potting & Encapsulation

- Provides complete protection from moisture, dust, and chemicals

- Enhances thermal management and heat dissipation

- Prevents damage from mechanical shock and vibration

- Improves electrical insulation

- Increases product reliability and lifespan

- Provides protection for sensitive IP within a potted enclosure

Why Choose Us for Potting & Conformal Coating?

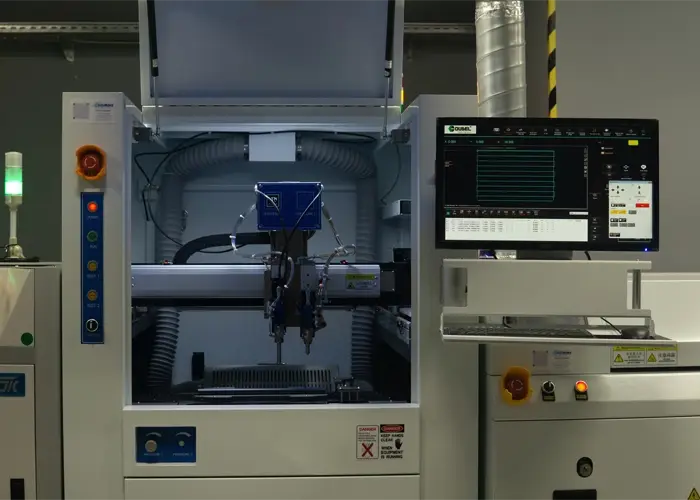

- Precise Coverage: We use spray systems in a ventilated booth to ensure an even and complete coating.

- Custom Solutions: Tailored coatings and potting materials based on your specific application.

- Quality: Inspection under UV light to verify coating application.

- Flexible: We can dispense potting compounds from 2 part mix pouches or utilise our meter mix equipment for higher volume, precision fill requirements.

Frequently Asked Questions (FAQs)

What is the difference between conformal coating and potting?

Conformal coating is a thin, protective film applied to the surface of a PCB, whereas potting fully encases the entire electronic assembly in a resin for maximum protection.

How do you ensure uniform coating coverage?

We use spray coating systems and UV inspection methods to verify complete and even coverage of the PCB assembly.

Can conformal coating be removed or repaired?

Yes, certain coatings like acrylic and silicone can be removed or repaired, while others like parylene require specialized techniques.