Surface Mount Technology Assembly Services

Experience Superior Quality and Efficiency in Every PCB with Our State-of-the-Art SMT Assembly services.

Get A Free Quote

High-Precision Surface Mount PCB Assembly

By utilising the latest manufacturing equipment and technologies Contract Production provide high quality, competitive SMT assembly services to a wide range of industries. Whether you require prototyping, pre-production or low-to-mid volume production PCB assembly, our state-of-the-art SMT manufacturing lines ensure high quality and reliability is built in to everything we manufacture.

What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method of mounting electronic components directly onto the surface of a Printed Circuit Board (PCB) rather than inserting them through holes (Through-Hole Technology – THT). This technique enables compact, lightweight, and highly efficient electronic assemblies, ideal for modern technology-driven industries.

Our SMT Assembly Capabilities

2 SMT production lines equipped with the latest component placement and inspection equipment, delivering high-quality PCB assemblies.

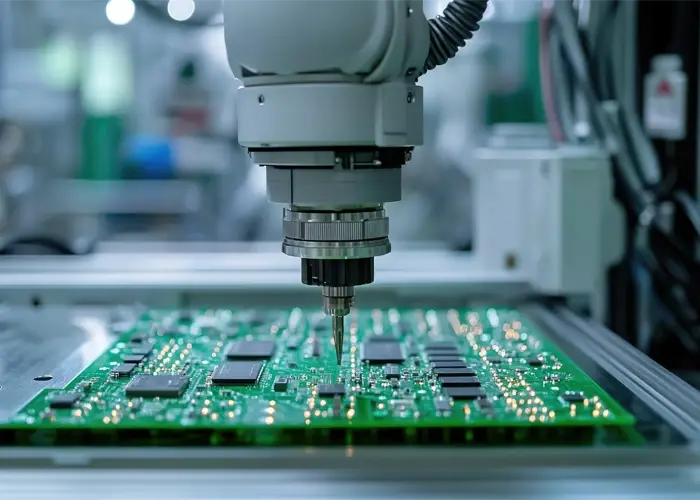

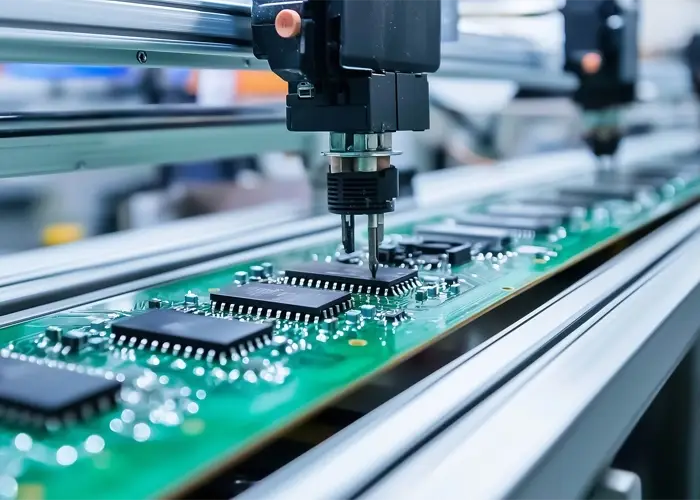

Automated SMT Assembly

Our 2 high-speed pick-and-place lines ensure an accurate, consistent and repeatable placement and reflow process for SMT assemblies complimented by 2 x 8 Zone Reflow ovens and cutting edge end of line 3D AOI inspection capabilities.

Fine-Pitch, High Density Component Placement

We can place high density fine pitch components, including:

- 0201 component footprints,

- Ball Grid Arrays (BGAs),Micro BGA’s (uBGA), Quad Flat Packages (QFPs), Chip Scale Packages (CSPs)

Lead-Free & RoHS-Compliant Soldering

We offer lead-free, RoHS-compliant soldering for environmentally friendly electronics manufacturing. Leaded solder (60/40 SnPb alloy) is also available upon request.

PCB Technologies

We manufacture and assemble on to a wide variety of PCB technologies including:

- Single Sided Boards

- Double Sided Boards

- High layer count Multi-Layers

- Metal backed PCB’s (IMS)

- Flex-Rigid PCB’s.

PCB Prototyping & Low-Volume Production

We provide machine build prototype/low volume PCB assemblies for pre-production and design verification as well as medium volume production runs.

Industries We Serve

We provide PCB assembly services to a wide range of industries, including:

- Automotive (AVAS Systems)

- Industrial Electronics (System Monitors)

- Oil and Gas (Downhole Drilling)

- Sub Sea Exploration (Remotely Operated Rovers)

- Sound and Environmental Monitoring

- Fire Safety and Suppression

- Laboratory Equipment

Our SMT Manufacturing Process

We follow a structured SMT PCB assembly process to ensure consistency and quality:

Manufacturing Review

DRC and DFM analysis of PCB data and BOM

Solder Paste Application

Precise application of solder paste with automated under stencil cleaning

Component Placement

High speed, accurate SMT component placement

Reflow Soldering

8 Zone reflow

for precise, controlled soldering

3D AOI Inspection

Sate of the art

end of line inspection

Inspection and Test

Final assembly inspection and verification