PCB Assembly Services

Expert PCB assembly services for projects of any size and industry, delivering reliable, high-quality electronic manufacturing solutions.

Get A Free Quote

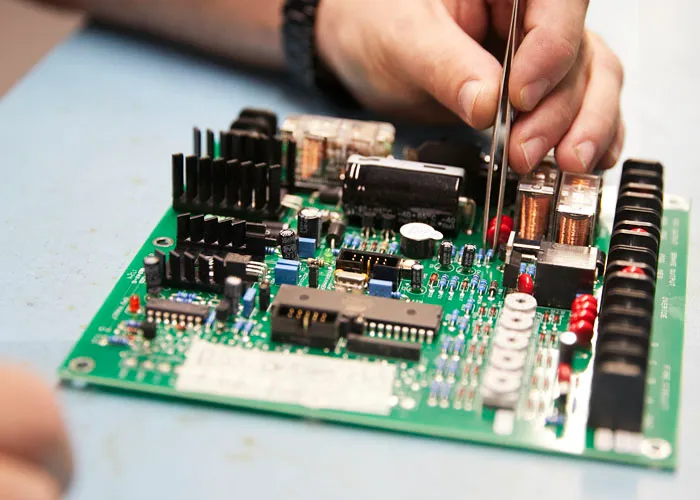

State-of-the-art PCB assembly services

Contract Production has years of experience in the manufacturing of complex electronic assemblies and products, working to the strictest quality standards. We provide electronic assemblies and complete box builds for a wide variety of customers and OEMs, spanning a broad range of technology sectors.

PCB Assembly

At Contract Production we have 2 fully equipped Panasonic AM100 SMT placement lines each capable of placing the most challenging components, including fine pitch high pin count BGAs, micro BGAs and 0201 component footprints with repeatable precision and accuracy. These are complemented by 2 state-of-the-art 8-zone reflow ovens and post-flow 3D AOI inspection capabilities delivering high quality, reliable PCB assemblies every time.

In addition to our automated SMT process, we also assemble through-hole components where surface-mount technology may be either impractical or unavailable. Through-hole components can be soldered on our Seho wave soldering equipment or where necessary expertly hand soldered by our IPC trained assembly staff allowing us to offer a truly comprehensive and flexible service for all of your surface mount and mixed technology PCB assembly requirements.

Why choose Contract Production for your PCB assembly?

Trusted by leading industries, we combine expertise, technology, and quality to deliver PCB assemblies you can depend on.

Committed to Growth and Innovation

Your Trusted UK PCB Assembly Partner

Our goal is to build long-term relationships with our clients, and our experienced assembly engineering staff thoroughly review all supplied data prior to manufacture to optimize assembly tooling and PCB panelisation for maximum yield and process efficiency, preventing the introduction of timely and costly errors later in the production cycle.

Proven Expertise

With years of experience in contract electronics manufacturing, our skilled engineers ensure precision, reliability, and compliance with international standards at every stage of production.

Cutting-Edge Facilities

We continuously invest in advanced equipment, including SMT lines, reflow ovens, and 3D automated inspection, to deliver high-quality assemblies at scale.

Quality Without Compromise

Accredited to ISO standards and IPC-certified, our processes are built around rigorous testing and inspection to guarantee fault-free, long-lasting performance.

Flexible & Scalable Solutions

From prototypes to high-volume production, we tailor our services to your unique needs, ensuring efficiency, cost-effectiveness and consistent quality at every stage.

Memberships & Accreditations

Commitment to Quality and Compliance:

ISO 9001:2015 & IPC-A-610 Standards

We are an ISO 9001:2015 accredited company and in addition to this certification, all our electronic assemblies are manufactured, inspected and released to the latest revision IPC-A-610 standard. Our in-house IPC-certified trainer ensures that ongoing compliance to the latest standard is maintained, providing the highest levels of confidence in our manufacturing procedures and processes at all times.

Quality Assured In Every Job

Contract Production is committed to providing high-quality PCB assembly services and products. Stringent internal quality assurance procedures ensure that all finished products and PCBs are manufactured and produced to consistently high standards. All bare PCBs are manufactured on UL-approved laminates and are 100% electrically tested.

Our PCB assembly solution at a glance

- 2 x Automated SMT pick and place lines

- 0201 and µBGA footprints

- Post-flow 3D AOI

- Through-hole assembly

- Lead-free wave soldering

- Leaded PCB assembly (60/40 SnPb Solder)

- Ultrasonic cleaning

- Full box build assembly

- Device programming and testing

Frequently Asked Questions (FAQs)

What types of PCBs do you assemble?

We assemble a wide range of PCB Technologies including:

- Single-sided PCB’s

- Double-sided PCB’s

- Multilayer PCB’s

- Metal backed (IMS) PCB’s

- Flex-Rigid PCB’s

What is the minimum order quantity for PCB assembly?

We offer flexible production runs, from small batches (low-volume) to large-scale production. There is no strict minimum order quantity so please feel free to contact us for a tailored quote based on your needs, no matter how large or small.

Can you do prototype PCB assembly?

Yes, we manufacture small batch runs and prototype PCB assemblies so customers can check and verify their designs prior to commiting to larger scale production volumes.

Do you offer testing services for PCB assemblies?

Yes, we offer a comprehensive range of testing and verification services using bespoke or customer supplied equipment and test schedules including.

- In-circuit testing (ICT)

- Functional testing

- X-ray inspection

- Device programming

Do you offer rework and repair services for PCB assemblies?

Yes, we provide SMT rework and repair services for PCBs that require adjustments after initial assembly. Whether it’s replacing faulty components, fixing soldering issues, or correcting design errors, our team can assist with repairs and rework to meet quality standards.

Is your PCB assembly process RoHS-compliant?

Yes, our PCB assemblies are RoHS-compliant (Restriction of Hazardous Substances), we source RoHS-compliant components and use lead-free solder alloys in our SMT and through-hole soldering processes (wave and bench). Certain customers and industry sectors still mandate the use of leaded solder in their PCB assemblies (60/40 SnPb solder) and we can also accommodate this process upon request.

Can you help with component sourcing for my PCB assembly?

Yes, we can source and procure all components necessary for the manufacture of your PCB assembnly project from your BOM. We only use approved suppliers and distributors but also have access to a group of verified off shore vendors who can source obsolete, end of life and hard to find components.

What quality control measures do you have in place?

We maintain rigorous quality control throughout the assembly process:

- Pre-production checks to verify design files and suitability for manufacturing.

- 3D Automated Optical Inspection (3D AOI) to verify and highlight any potential defects during the SMT process.

- Final inspection – for verification of the completed assembly to drawing specifications.

- Functional testing to verify that the PCB performs as intended.

Do you ship internationally?

Yes, we ship globally. We use reliable shipping carriers to deliver your PCBs securely and on time. Shipping costs vary based on location and order size. We can also offer expedited shipping options for urgent projects.