Our Electronics Manufacturing Process

Seamless Electronics Manufacturing – Precision, Quality, Reliability & Efficiency at Every Step

Get A Free Quote

Our Manufacturing Process

Quality, Precision, Flexibility & Efficiency

At Contract Production, we provide comprehensive electronics manufacturing services, from initial design and engineering to final product testing. Whether you need low volume pre-production prototypes or higher volume production runs, we ensure high-quality, reliable, and cost-effective manufacturing solutions tailored to meet your individual requirements.

1. Production Engineering – Optimised for Efficiency

The manufacturing process begins with a thorough review of all supplied data, designs, and drawings to ensure they align with our PCB manufacturing design rules and process parameters. Our engineering team identifies and resolves any potential issues with you before production, saving you time and costs whilst optimizing process tooling for manufacturing efficiency and quality.

Key Benefits:

- Design for Manufacture Analysis (DFM)

- Component Placement & Machine Programme Optimisation

- Optimisation of Process Efficiency

- Cost Saving Pre-Production Engineering Solutions

2. Component Procurement – Quality & Cost Savings

We manage the entire component sourcing and procurement process, leveraging our strong relationships with trusted partners and suppliers to secure high-quality components at competitive prices. Our strict supply chain management ensures we only source and purchase from proven, reliable suppliers ensuring all components are authentic and fit for purpose.

Why Choose Our Procurement Services?

- Cost Savings Through Bulk & Strategic Sourcing

- Strict Quality Control & Vendor Screening

- Guaranteed Traceability & Compliance (RoHS, REACH, UL)

- Mitigating Supply Chain Risks & Shortages

- Obsolescence and Product Change Notification (PCN) Management

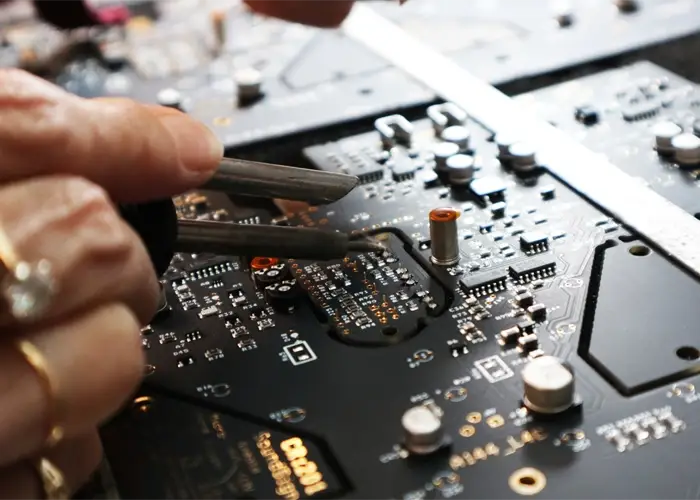

3. PCB Assembly – Manufacturing Capabilities

We specialize in precision PCB assembly manufacturing, catering for SMT and through hole technologies, lead free and leaded PCB assembly on single sided, double sided, multilayer and flex-rigid UL approved PCB’s

Our PCB Assembly Process Includes:

- Surface Mount Technology (SMT) Assembly – High-speed, precision component placement.

- Through-Hole Assembly – Lead free and leaded solder alloys.

- Mixed Technology Assembly – Through hole and SMT components.

- 3D Automated Optical Inspection (3D AOI) – Robust post flow SMT assembly inspection.

4. Inspection & Testing – Process Quality

All PCBs and electronic assemblies undergo rigorous in process inspection routines to guarantee functional reliability. This can include X-Ray inspection and final assembly testing utilising bespoke customer supplied equipment and test procedures.

Inspection & Testing Methods:

- 3D Automated Optical Inspection (3D AOI)

- X-ray Inspection (on request)

- In-Circuit Testing (on request)

- Functional Testing (on request)

5. PCB Protection – Conformal Coating and Potting

To enhance PCB longevity and protect electronic assemblies against moisture ingress and harsh environmental conditions, we offer a range of conformal coating and potting services.

Our Protective Solutions Include:

- Spray application of Acrylic and Polyurethane conformal coatings

- Black light UV Light Inspection to ensure even and consistent coverage

- Dedicated spray booth with precision spray applicator guns

- Final enclosure potting for critical safety requirements and IP protection

6. Box Build – Full Product Assembly & Test

For complete turnkey solutions, we offer box build services, assembling fully functional electronic products, including:

-

Cable & Wire Harness Assembly

-

PCB & Enclosure Integration

-

Firmware Programming & System Testing

-

Final Product Packaging & Labeling

Explore Our Box Build Capabilities