Lead Free Wave Soldering

Precision, Efficiency and Consistency – High quality wave soldering for reliable PCB Assemblies

Get A Free Quote

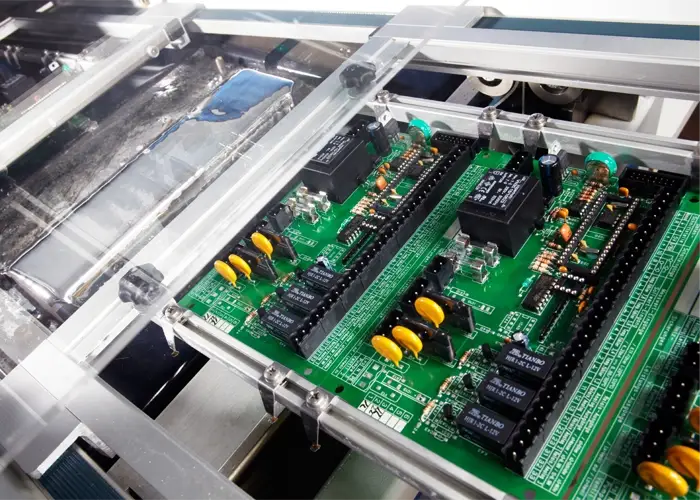

Wave soldering is a semi-automated process that involves passing a printed circuit board (PCB) under controlled thermal conditions over a wave of molten solder to provide reliable solder joints on a PCB assembly. This soldering method yields consistent, high-quality solder joints and improves production efficiency by reducing rework and improving process times. At Contract Production we use Seho process equipment to ensure precise and repeatable solder joint quality on our PCB assemblies.

Our Wave Soldering Process

We adhere to strict process parameters to deliver optimal results:

- Flux Application: A precise layer of flux is sprayed across the board surface to clean and activate exposed component pads, ensuring optimal wetting and solder joint formation.

- Preheating: The assembled PCB is pre-heated under controlled conditions using Infra Red and Quartz heating elements to activate the flux and prevent any thermal stress to the PCB at the wave stage.

- Wave Soldering: The board passes over a wave of molten lead free solder at a precise speed, temperature and height creating strong and uniform solder joints.

- Cooling: The solder solidifies under controlled cooling conditions to prevent post-flow joint defects and enhance solder durability.

Wave Soldering – Process Features

Our Seho Lead Free Wave Soldering Equipment provides precision, efficiency, and reliability to our soldering process and includes include features such as:

- Advanced Conveyor System: Ensuring smooth board transport and component stability during reflow.

- Twin Wave System: Capable of soldering SMT and through hole components simultaneously.

- Adjustable Wave Height: Can be optimised to accommodate varied soldering requirements and technologies.

- Automated Spray Fluxing & Preheating: Controlled flux application and thermal management of the PCB for consistent soldering results.

- Process Control: Regular thermal profiling and solder analysis to optimise the wave soldering process.

Why Choose Our Wave Soldering Services?

We offer industry-leading services with several advantages:

- Precision & Consistency: Our advanced equipment ensures uniform and reliable soldering results across all board types.

- Cost-Effective: Wave soldering reduces labour time and enhances process efficiency.

- High Quality Alloys: We only use high purity RoHS compliant SAC305 lead free solder alloy with a high performance flux for optimum solder joint quality and consistency.

Frequently Asked Questions (FAQs)

What types of PCBs are suitable for wave soldering?

Wave soldering is ideally suited to through-hole components but our dual wave configuration can also accommodate some mixed technology boards assembled with both surface mount and through-hole components.

What are the benefits of using wave soldering over manual soldering?

It is faster, more consistent, and cost-effective for high-volume PCB assembly compared to manual soldering.

Is your lead-free wave soldering process RoHS Compliant?

Yes, we provide lead-free soldering which is RoHS compliant and use high purity SAC305 alloys in our solder pot.

How do you ensure high-quality solder joints?

We use wave soldering equipment with optimized spray fluxing, preheating, precise thermal profiling and process monitoring to ensure consistent, defect-free solder joints.