PCB Assembly Testing Services

Ensure Quality and Reliability with PCB Assembly Testing Services

Get A Free Quote

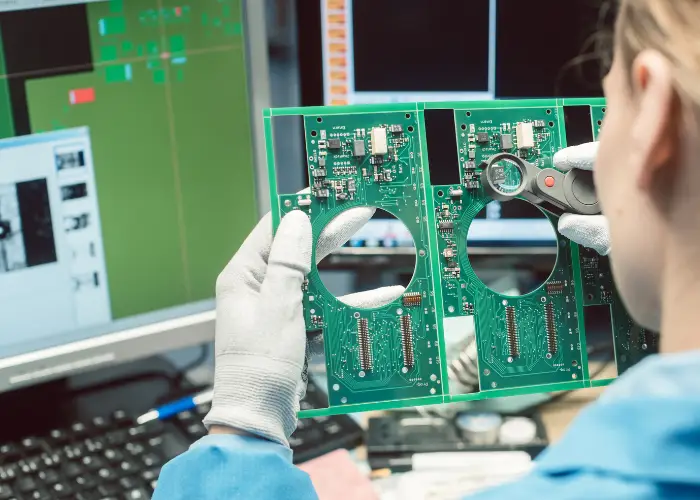

PCB Assembly Testing

While various quality control and inspection checks are performed during the production cycle, functional testing remains the most reliable method for confirming the integrity and reliability of a finished PCB assembly. Whether it’s a basic input/output procedure or a more robust test utilising your own bespoke equipment, we can provide testing services to ensure confidence in the functionality and reliability of your completed PCB assembly.

What is PCB Assembly Testing?

PCB assembly testing is a quality control process used in electronic manufacturing to identify potential problems during the assembly process. It involves systematically testing each component and connection on the board to ensure it functions as specified based on the original design requirements.

Why choose Contract Production for PCB engineering, design and functional testing?

At Contract Production, we can provide comprehensive in-house PCB programming and testing services to ensure your electronic assemblies meet expected performance standards before dispatch. We can utilise customer-designed test rigs and schedules to verify the functionality of your PCB assembly. We also provide chip/firmware programming of IC’s and BGAs with supplied code using industry-standard hardware and software programming platforms. In addition, we can also provide test result logging, recording critical data against individual serial numbers for full product traceability if required.

Our PCB Functional Testing Service at a Glance

- Utilisation of bespoke or supplied test kit

- Device Programming

- Functional Testing (FCT)

- JTAG

- Result Logging for Product Traceability

- Serial numbering

Frequently Asked Questions (FAQs)

Why is PCB functional testing important?

Functional testing provides confidence that a PCB assembly is functioning as intended, eliminating the need for potentially costly rework and repair.

What types of functional tests do you perform?

Testing requirements vary from customer to customer so we have a wide array of test equipment and programming devices ensuring we can accommodate functional testing to a pre determined schedule utilising either in-house or customer supplied equipment.

Do you offer (ATE) automated functional testing?

Yes, automated testing is predominantly used on volume production and we have access to test engineering services who can manufacture bed of nails test equipment to facilitate automated functional testing (ATE).

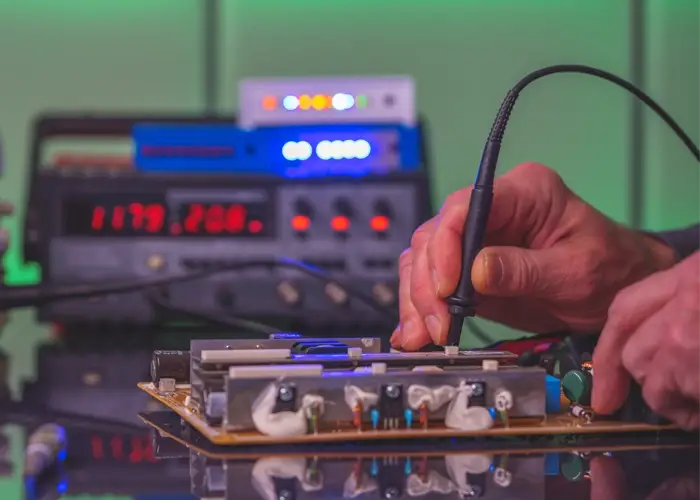

What equipment do you use for functional testing?

Our test setup includes oscilloscopes, signal analyzers, spectrum analyzers, logic analyzers, power supplies, and custom test fixtures.

Can you test small and large production batches?

Yes, we handle both prototype testing and large-scale production testing.