PCB Prototyping Services

Efficient, Reliable PCB Prototyping Services for Rapid Product Development and Testing

Get A Free Quote

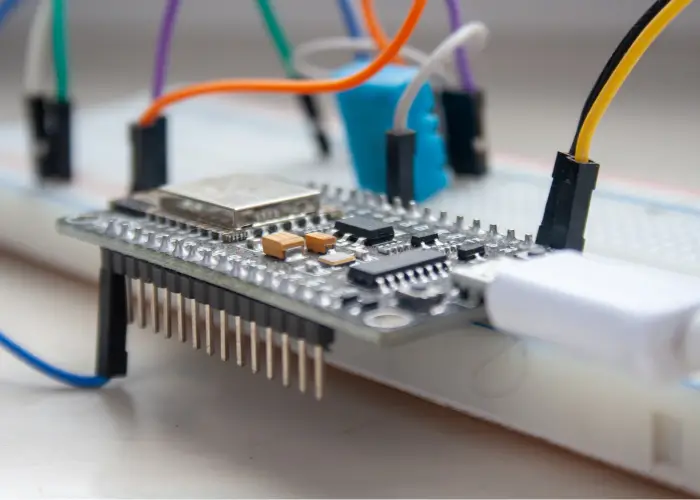

PCB Prototyping Services for Rapid Product Development

What is PCB prototyping?

PCB assembly prototyping is an important step in the development of an electronic device or assembly.

Producing a small batch of pre-production PCBA’s or even a single prototype allows designers and engineers to prove, amend and refine their designs before committing to full-scale production, preventing time consuming and costly rework.

Why choose Contract Production for PCB prototyping?

Many of our valued, long-term customers first approached us for PCB prototyping services, seeking a partner they could trust to help with the development and production of a new electronic design or project. Our ability to blend small batch prototypes alongside higher volume production provides our customers with a manufacturing partner who is capable of seamlessly and efficiently transitioning a design from test board to full production spec, all under one roof.

Our PCB prototyping solution at a glance

- PCB Manufacture & Assembly

- Component Procurement

- Firmware Loading & Device Programming

- Potting, encapsulation and heat shrinking

- Machine and Hand Assembly

- Testing (on request)

Frequently Asked Questions (FAQs)

What is PCB prototyping?

PCB prototyping is the process of manufacturing single or small quantities of a PCB Assembly to test and validate its design and functionality prior to volume mass production.

What is the leadtime for a prototype?

We always aim to accommodate quicker turnaround times for prototypes, but this can vary from project to project depending on the amount of components on the PCB and design complexity.

What factors influence the cost of PCB prototyping?

The cost of PCB prototyping can vary based on several factors, such as the number of layers, the size of the board, the complexity of the design, material selection, and any additional requirements such as special finishes or testing.

What information do I need to provide to get a PCB prototype?

To get started with your PCB prototype, we typically require your design files (usually in Gerber or similar formats), as well as any specific requirements for the board’s materials, size, layers, and finishes.

Do you perform testing on PCB prototypes?

All of our bare boards are 100% electrically tested prior to assembly.

Testing of the final assembly can be carried out upon request.