Modern vehicles are no longer purely mechanical; they are complex electronic ecosystems. From engine control units (ECUs) to advanced driver-assistance systems (ADAS), automotive electronics are responsible for safety, efficiency, comfort, and entertainment.

Unlike consumer electronics, automotive components must survive a brutal operating environment: extreme temperatures, high vibration, voltage fluctuations, and years of continuous operation.

That’s why precision manufacturing and adherence to strict automotive standards are non-negotiable.

We specialise in manufacturing high-reliability electronics, combining technical excellence with precision and quality to ensure products perform flawlessly.

In this guide, we’ll explore:

-

- The High-Stakes World of Automotive Electronics

- Key Automotive Electronics Standards

- Common Manufacturing Challenges in Automotive Electronics

- Precision Manufacturing for Automotive Electronics

- Best Practices for Meeting Automotive Standards

- The Role of Collaboration in Automotive Manufacturing

- Emerging Trends in Automotive Electronics Manufacturing

- Frequently Asked Questions (FAQs)

- Conclusion

1. The High-Stakes World of Automotive Electronics

In automotive electronics, failure isn’t an option. A malfunction in infotainment may be inconvenient, but a failure in braking or steering control can be catastrophic.

This is why automotive electronics must:

-

- Operate in temperatures from -40°C to +125°C.

- Withstand constant mechanical vibration.

- Tolerate voltage fluctuations.

- Maintain performance for 10–15 years or more.

At Contract Production Ltd, we design and manufacture electronics to the highest standards, ensuring reliable performance even in the most demanding conditions.

2. Key Automotive Electronics Standards

ISO 26262 – Functional Safety

-

- Ensures the safety of electrical/electronic systems in road vehicles.

- Applies to all safety-related components, from airbags to braking systems.

- Uses the ASIL (Automotive Safety Integrity Level) classification.

IATF 16949 – Quality Management

-

- Automotive-specific quality management standard.

- Combines ISO 9001 with sector-specific requirements.

- Focuses on continuous improvement and defect prevention.

IPC-A-610 – Electronics Assembly Acceptability

-

- Defines quality standards for electronic assemblies.

- For automotive, Class 3 (high-reliability) is typically required.

AEC-Q100 / AEC-Q200 – Component Qualification

-

- Stress testing standards for semiconductors and passive components.

- Ensures components are automotive-grade before assembly.

ISO 21434 – Cybersecurity for Automotive

-

- Protects against cyber threats in connected and autonomous vehicles.

3. Common Manufacturing Challenges in Automotive Electronics

Extreme Environmental Conditions

Automotive components face:

-

- Thermal cycling: Rapid shifts between hot and cold.

- High humidity: Risk of corrosion.

- Road vibration: Can cause solder joint fatigue.

Solution: Use high-temperature-rated components, vibration-resistant solder joints, and conformal coatings.

Long Product Lifecycles

A car model may be in production for 7–10 years, but spare parts must be available even longer.

Solution: Design for long-term component availability and plan for obsolescence management.

Safety-Critical Reliability

Failure in systems like braking or steering can lead to fatalities.

Solution: Use redundancy, fail-safe design, and rigorous testing protocols.

Cost vs. Compliance

Meeting all standards can be costly, but skipping them is not an option.

Solution: Optimise DFM (Design for Manufacture) to balance compliance with production efficiency.

At Contract Production Ltd, we apply these solutions to keep our clients ahead of both operational challenges and market competition.

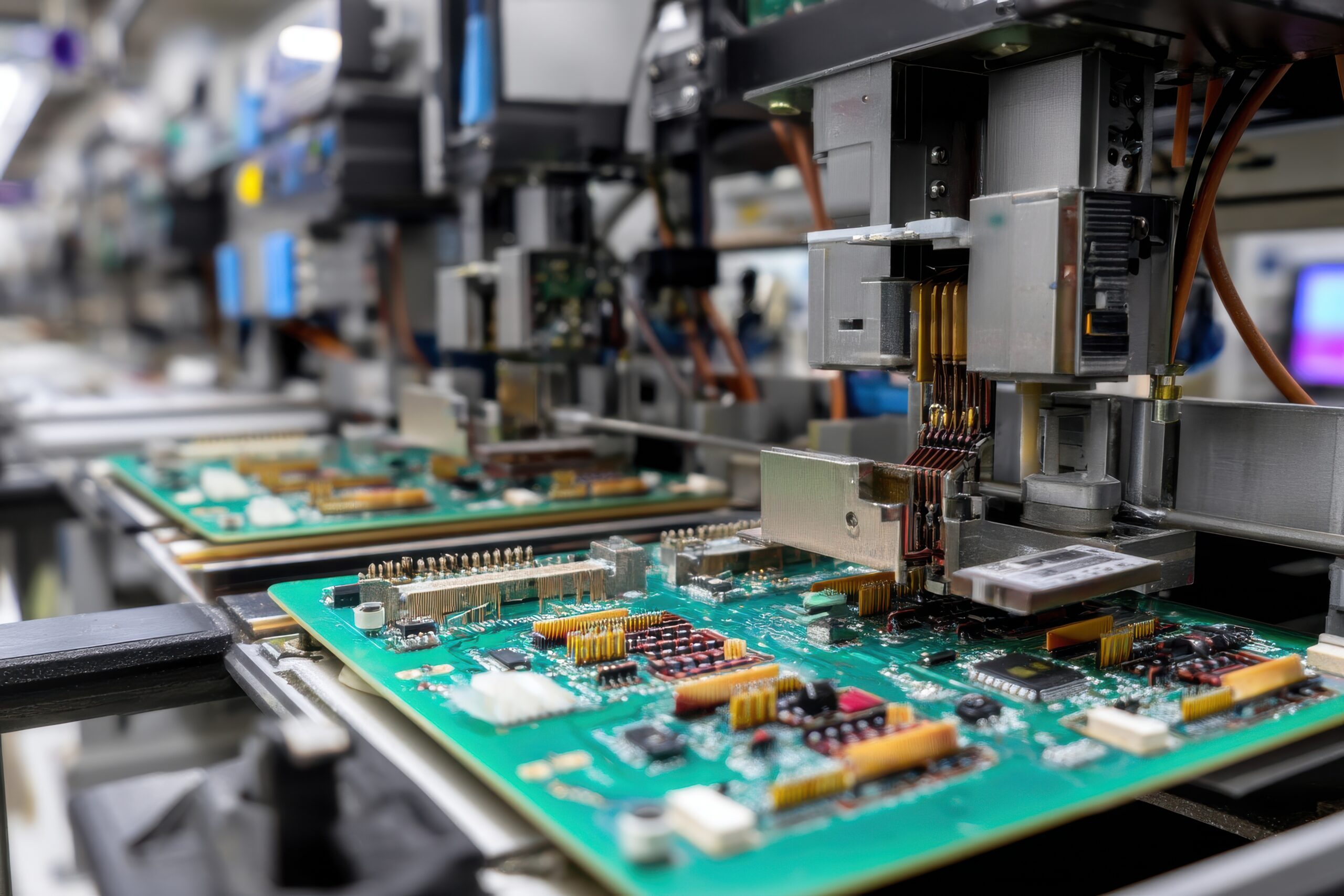

4. Precision Manufacturing for Automotive Electronics

PCB Design Considerations

-

- Material choice: High Tg (glass transition temperature) laminates for heat resistance.

- Controlled impedance traces for high-speed signals (ADAS, infotainment).

- Thermal relief pads for high-current components.

Assembly Process Controls

-

- Automated optical inspection (AOI) after every critical stage.

- X-ray inspection for BGAs (ball grid arrays).

- Solder paste inspection (SPI) for consistency.

Testing & Validation

-

- Burn-in testing: Operating the electronics under load for extended periods to detect early failures.

- Environmental stress screening (ESS): Simulating real-world conditions.

- In-circuit testing (ICT): Checking the electrical performance of individual components.

These processes are essential at Contract Production Ltd, ensuring that every board leaving our facility is ready for the road.

5. Best Practices for Meeting Automotive Standards

Engage with Manufacturers Early

Early design reviews prevent costly redesigns for compliance.

Use Automotive-Grade Components

Standard consumer components may fail under automotive conditions.

Implement 100% Traceability

Essential for recalls and root cause analysis.

Conduct Life-Cycle Testing

Simulate years of usage in a compressed timeframe.

Maintain Cleanroom Conditions

Reduces contamination risks for sensitive electronics.

6. The Role of Collaboration

Meeting automotive standards is about more than passing audits; it’s about creating an integrated partnership between design, manufacturing, and quality teams.

With Contract Production Ltd, you gain a UK-based manufacturing partner that:

-

- Works closely with your engineers.

- Focuses on efficient, high-quality production.

- Delivers reliable, high-performance electronics every time.

7. Emerging Trends in Automotive Electronics Manufacturing

-

- Electrification: High-voltage systems for EVs require new insulation and safety approaches.

- ADAS & Autonomous Driving: More sensors, cameras, and computing power demand complex PCBs.

- Lightweighting: Reducing PCB and enclosure weight for fuel efficiency.

- Over-the-Air Updates: Cybersecurity and software integrity become critical.

8. Frequently Asked Questions (FAQs)

Q1: Are automotive-grade components always necessary?

Yes, for safety-critical systems. For non-critical applications, alternatives may be possible if thoroughly tested.

Q2: Can products be certified after manufacturing?

No. Compliance must be built into the design and production process from the start.

Q3: What’s the difference between ISO 26262 and IATF 16949?

ISO 26262 ensures functional safety; IATF 16949 ensures robust quality management across the supply chain.

Q4: How often do standards change?

Standards and best practices evolve regularly. Products need to be reviewed periodically to ensure they remain safe, reliable, and up to current requirements throughout their lifecycle.

Conclusion

Precision manufacturing in the automotive electronics sector is about more than making a PCB; it’s about ensuring safety, reliability, and compliance for components that operate in some of the harshest environments imaginable.

By understanding and meeting automotive standards like ISO 26262, IATF 16949, and AEC-Q100/200, manufacturers can deliver products that perform flawlessly for a decade or more, protecting lives and brand reputations alike.

If you’re developing an automotive electronics project, partnering with a manufacturer experienced in both the technical and compliance aspects of the sector is the smartest route to success.

Contract Production Ltd offers the experience, certified processes, and advanced manufacturing capabilities to deliver electronics that meet the toughest global requirements. From design support to full-scale production, we ensure your components perform flawlessly mile after mile, year after year.

Ensure your automotive electronics are safe, dependable, and reliable. Contact our expert and friendly team on +44 (0)1751 475950 or sales@contractproduction.co.uk