In electronics manufacturing, two primary techniques dominate the process of mounting components onto printed circuit boards (PCBs): Surface Mount Technology (SMT) and Through-Hole Technology (THT).

While SMT has become the preferred choice for most modern, high-volume production due to its efficiency and ability to support miniaturisation, through-hole technology still holds a vital place in industries such as automotive, aerospace, defence, and industrial controls, where mechanical durability and long-term reliability are non-negotiable.

For engineers, PCB designers, and procurement professionals, understanding these two assembly methods, their strengths, limitations, and ideal applications is crucial for making cost-effective and performance-driven manufacturing decisions.

As a contract electronics manufacturer, Contract Production Ltd has extensive expertise in both SMT and through-hole processes, often implementing hybrid PCB assembly solutions to meet the unique needs of clients across sectors. This guide will walk you through the fundamentals, give you practical insights, and help you determine the best approach for your next PCB project.

In the following sections, we’ll uncover:

-

- What is Surface Mount Technology (SMT)?

- What is Through-Hole Technology (THT)?

- SMT vs. THT: A Side-by-Side Comparison

- Hybrid PCB Designs

- Industry Applications

- Key Design Considerations

- Cost Factors

- Future Trends in PCB Assembly

- Frequently Asked Questions (FAQs)

- Conclusion

1. What is Surface Mount Technology (SMT)?

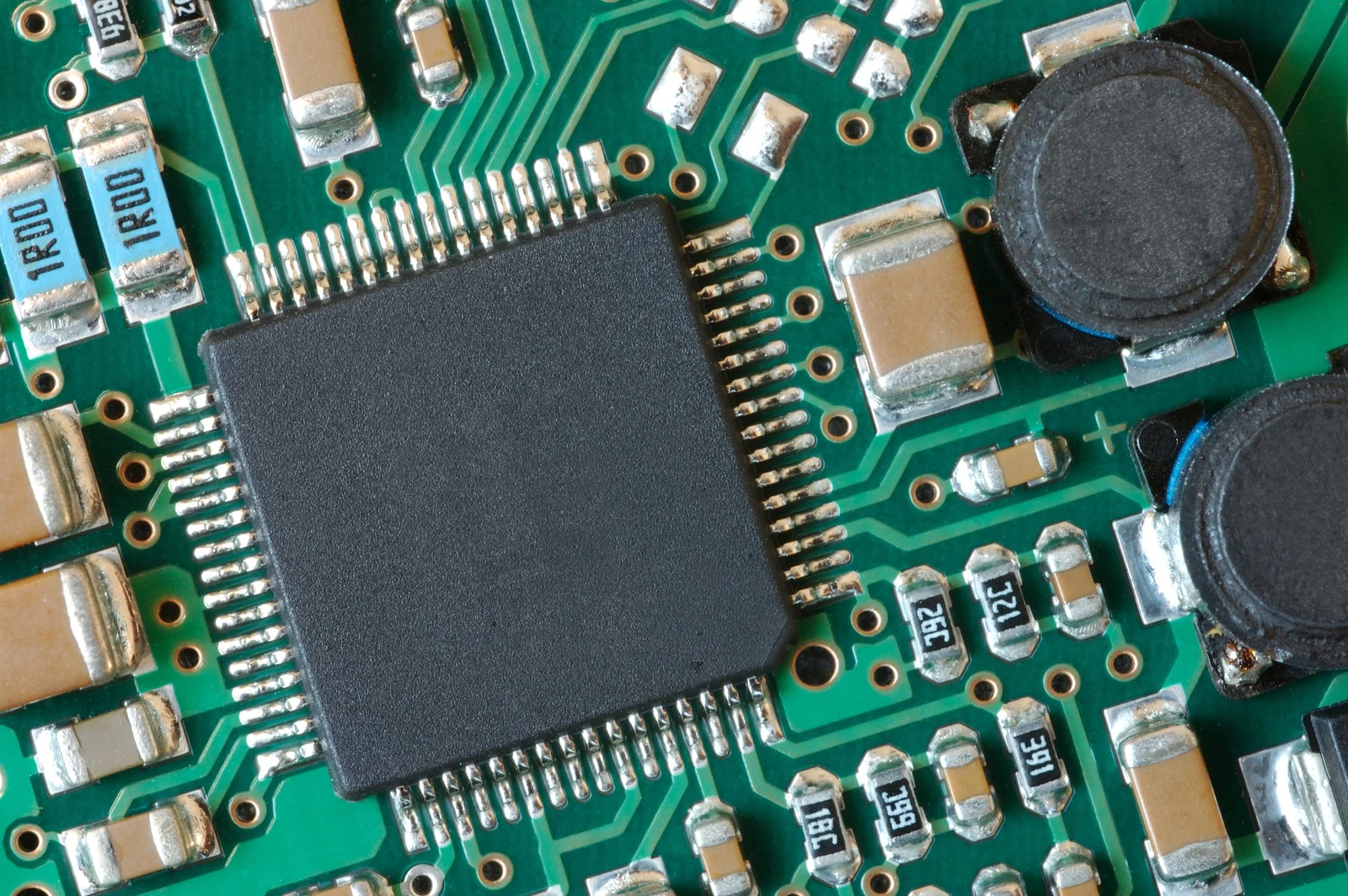

Surface Mount Technology is a process in which electronic components are mounted directly onto the surface of a PCB, without the need to drill holes for component leads.

SMT Manufacturing Process

-

- Solder Paste Application: Solder paste is applied precisely to the PCB pads using a stencil printer.

- Component Placement: High-speed pick-and-place machines position components with exceptional accuracy (often exceeding 50,000 components/hour).

- Reflow Soldering: The PCB passes through a reflow oven where solder paste melts, creating strong electrical and mechanical bonds.

- Inspection & Testing: Advanced inspection methods like Automated Optical Inspection (AOI) and X-ray scanning ensure quality.

Advantages of SMT

-

- Miniaturisation: Perfect for compact, high-density PCB designs.

- High-Speed Automation: Supports rapid mass production.

- Cost-Efficiency: Reduced manual labour and no drilling for leads.

- Electrical Performance: Shorter lead lengths improve high-frequency characteristics.

Limitations of SMT

-

- Less robust under mechanical stress.

- More complex rework and repair processes.

- Not ideal for certain high-voltage or high-power applications without careful design.

Get reliable, high-precision SMT assembly with Contract Production Ltd.

2. What is Through-Hole Technology (THT)?

Through-Hole Technology involves inserting component leads into drilled holes and soldering them to pads on the opposite side of the PCB.

THT Manufacturing Process

-

- Hole Drilling: Precision drilling ensures a perfect lead fit.

- Component Insertion: Placed manually or with semi-automatic equipment.

- Wave Soldering / Hand Soldering: Bonds leads to copper pads securely.

- Inspection & Testing: Rigorous checks for connection strength and quality.

Advantages of THT

-

- Superior Mechanical Strength: Ideal for vibration-prone or high-stress environments.

- Highly Reliable Electrical Connections: Leads pass through the board, creating stronger bonds.

- Great for Prototyping: Easier manual assembly and rework.

Limitations of THT

-

- Slower, less cost-efficient for high-volume production.

- Consumes more PCB space.

- Extra drilling steps add time and cost.

See how we support your THT PCB needs

3. SMT vs. THT: Side-by-Side Comparison

| Feature | SMT | THT |

| Component Size | Very small, suitable for high-density | Larger, requires more spacing |

| Mechanical Strength | Lower | Higher |

| Production Speed | Extremely fast with automation | Slower, more manual |

| Cost Efficiency | High for large production volumes | Lower in high-volume manufacturing |

| Best Use Cases | Consumer electronics, telecom, IoT | Automotive, aerospace, industrial equipment |

4. Hybrid PCB Designs

In many projects, the most effective solution isn’t either-or, it’s both. A hybrid PCB might use SMT for compact, high-speed signal components and through-hole technology for larger connectors or parts that require high durability.

Example Hybrid Layout:

-

- SMT: Microcontrollers, resistors, small capacitors.

- THT: Transformers, heavy connectors, large electrolytic capacitors.

At Contract Production, hybrid PCB assembly is a common solution we implement for clients in environmental monitoring systems and oil and gas sectors, ensuring both performance and durability are achieved without compromise.

5. Industry Applications

Consumer Electronics

SMT dominates for mobile devices, wearables, and compact gadgets.

Automotive Electronics

-

- Through-hole is favoured for components in high-vibration areas (engine control units, safety systems).

- SMT is used for infotainment, sensors, and control modules.

Aerospace & Defence

-

- Often a mix of SMT for signal processing and THT for mission-critical, vibration-resistant components.

Industrial Control Systems

-

- Power handling and high-reliability parts often require through-hole mounting.

6. Design Considerations

When choosing between SMT and THT or combining both, factors include:

-

- Electrical performance needs

- Mechanical stress tolerance

- Space limitations

- Production volumes

- Budget constraints

At Contract Production, design for manufacturability (DFM) is a core part of our process. We collaborate with clients from the early design phase, ensuring the chosen assembly method aligns with performance, cost, and scalability goals.

7. Cost Factors

-

- SMT: Higher equipment cost but faster production and lower per-unit labour cost.

- THT: More manual work, higher per-unit labour cost, but lower setup cost for small runs.

8. Future Trends

-

- Growing adoption of micro-SMT in IoT and medical devices.

- Automation in selective through-hole soldering.

- Integration of 3D-printed PCB structures for custom hybrid designs.

9. Frequently Asked Questions (FAQs)

Q1: Can a PCB use both SMT and THT?

Yes, and in many cases, it’s the best solution. This approach, called mixed assembly, allows designers to take advantage of the strengths of both techniques: SMT for compact, high-speed components, and THT for connectors or parts that require mechanical durability.

Q2: Which is better for high-frequency applications?

SMT is generally preferred for high-frequency applications because it offers shorter electrical paths, reducing inductance and resistance. This can lead to better signal integrity and reduced interference.

Q3: Is through-hole obsolete?

Not at all. While SMT dominates in most modern electronics, through-hole technology is still crucial for components exposed to mechanical stress, high heat, or environments that demand extreme reliability, such as aerospace, military, and heavy industrial applications.

Q4: Which is more cost-effective?

For large-scale production runs, SMT is typically more cost-effective due to automated assembly and smaller component sizes. However, for specialised low-to-medium volume projects, THT can be more practical, especially when durability or unique component shapes are needed.

Q5: Can SMT components handle high power?

Yes, but with design considerations. Heat dissipation becomes a key factor in high-power SMT designs, and additional cooling solutions (like heat sinks or thermal vias) may be required.

Q6: Do THT boards take longer to assemble?

Yes. Through-hole assembly often involves manual soldering or slower wave soldering processes, which can increase production time compared to fully automated SMT assembly lines.

Q7: Is repair easier with SMT or THT?

Generally, THT is easier to repair or replace due to its larger component sizes and robust lead connections. SMT repairs require specialised tools and skills, but they are still achievable with the right equipment.

Q8: Can I design a PCB entirely with SMT for all applications?

For most consumer electronics, yes. However, certain mechanical connectors, large capacitors, or high-durability components might still require through-hole mounting.

Conclusion

Choosing between SMT and THT is not simply about cost. It’s about understanding performance requirements, reliability standards, environmental factors, and production scale.

Contract Production Ltd offers both SMT and through-hole assembly under one roof, supported by advanced inspection systems, skilled technicians, and strict quality management processes. Whether you need high-volume consumer electronics or specialised, rugged industrial boards, our team delivers assemblies built to perform and built to last.

Make Contract Production Ltd your trusted partner for reliable SMT and THT assembly. Contact us today to discuss your project.

📞 01751 475950

📧 sales@contractproduction.co.uk

🌐 https://contractproduction.co.uk/get-a-quote